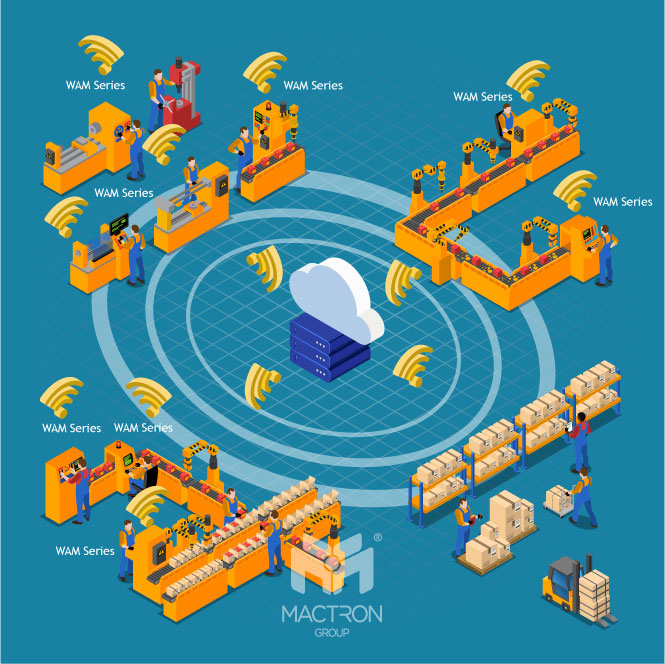

When your WAM meets HMI

The function of HMI

HMIs are used to optimize an industrial process by digitizing and centralizing data for a viewer. It can be used for monitoring and tracking, or for switching machines off and increasing production speed. By leveraging HMI, operators can see important information displayed in graphs, charts, and also view and manage alarms, all through one console.

Previously, operators would need to walk the floor constantly to review mechanical progress and record it on a piece of paper or a whiteboard. Now HMI technology eliminates the need for this outdated practice and thereby reduces many costly problems caused by lack of information or human error.

WAM applies to all industrialists

According to the Wirtschaftswoche in 2021, in Germany, factories that have moved to HMI systems in the past five years have reduced their manufacturing costs by about 27%, and the conversion profits are billions of euros, far beyond our imagination. This shows the combination of these devices and systems is an inevitable trend.

Check out MACTRON GROUP(MTG)’s brand new WAM Series. Our Panel Mount Touch Panel PC can adapt to all kinds of work environments with powerful performance, and combine with the HMI system. It can meet all your imagination.