Common Classifications Of Solid-State Drives

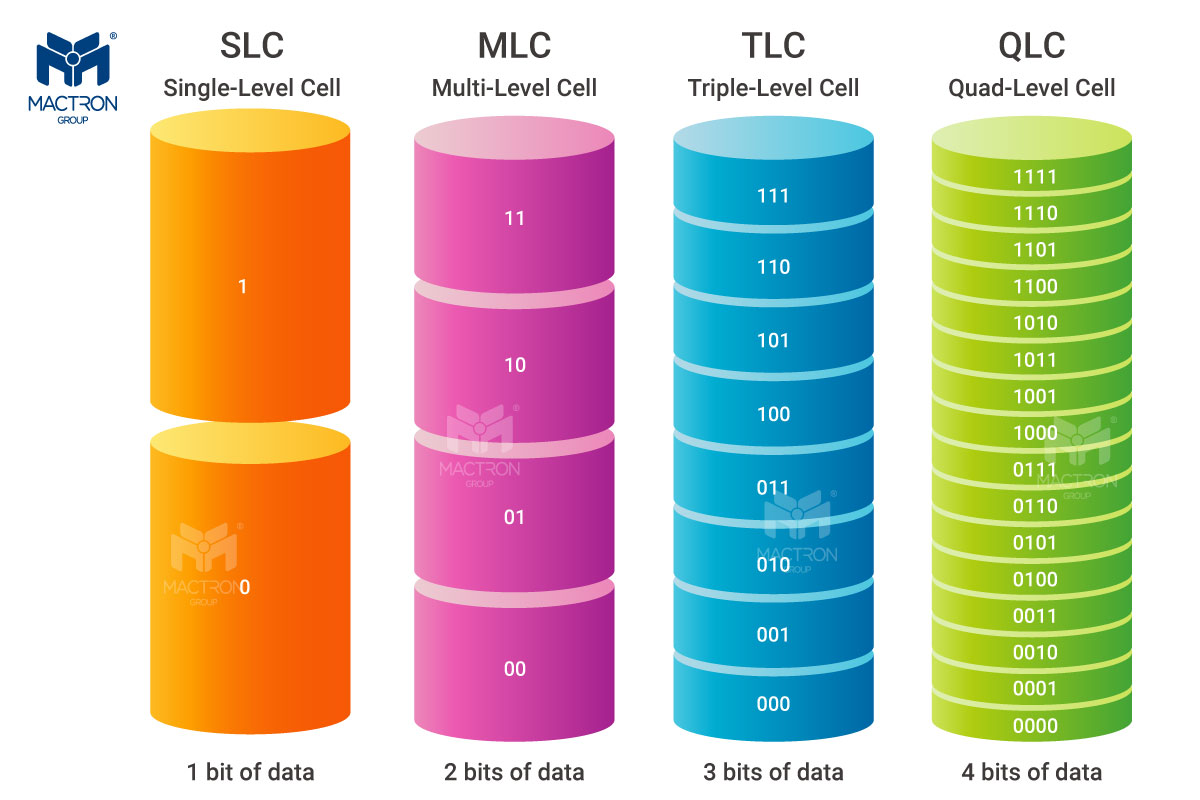

SLC (Single-Level Cell) SSD: Each storage unit stores only one bit of data, offering the highest performance and durability, but also the highest cost.

MLC (Multi-Level Cell) SSD: Each storage unit can store multiple bits of data, with lower cost but relatively lower performance and lifespan.

TLC (Triple-Level Cell) SSD: Each storage unit stores three bits of data, with even lower cost but further reduced performance and lifespan.

QLC (Quad-Level Cell) SSD: Each storage unit stores four bits of data, with the lowest cost but relatively lower performance and lifespan.

Based on usage:

Consumer-grade SSD: Suitable for general users, providing good performance and reliability.

Enterprise-grade SSD: With higher durability and reliability, suitable for high-load environments such as servers and data centers.

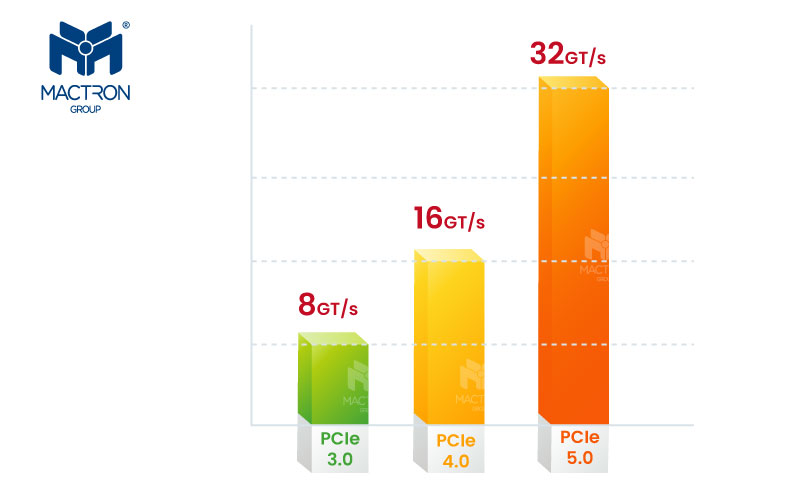

The data transmission differences between PCIe 3.0 and 5.0

The theoretical maximum transfer speed of PCIe 3.0 is 8 GT/s per lane (approximately 1 GB/s per lane).

The theoretical maximum transfer speed of PCIe 4.0 is double that of PCIe 3.0, at 16 GT/s per lane (approximately 2 GB/s per lane).

The theoretical maximum transfer speed of PCIe 5.0 is double that of PCIe 4.0, at 32 GT/s per lane (approximately 4 GB/s per lane).

Therefore, PCIe 5.0 offers higher bandwidth and data transfer speeds compared to PCIe 3.0, making it more suitable for high-performance computing and data center applications.

The theoretical bandwidth per lane of PCIe 3.0 is 8 GB/s.

The theoretical bandwidth per lane of PCIe 4.0 is 16 GB/s.

The theoretical bandwidth per lane of PCIe 5.0 is 32 GB/s.

PCIe 5.0 addresses the growing demand for data transfer speeds and performance by providing higher bandwidth.

PCIe 5.0 is backward compatible, meaning that PCIe 5.0 devices can be compatible with previous versions of the PCIe interface (such as PCIe 4.0, PCIe 3.0), albeit at reduced speeds. Similarly, previous version devices can also be connected to PCIe 5.0 slots but will operate at lower speeds.

PCIe 5.0 introduces new power supply specifications to support higher bandwidth and performance. This may require new hardware designs and power solutions to ensure system stability.

PCIe 5.0 introduces new security features and protocols to enhance the security and integrity of data transmission. This is crucial for protecting sensitive data and ensuring secure data transmission.