The military drop test is a certification that many 3C products will have, especially in the industries, this certification is even one of the basic conditions. Let's take a deeper look at how it works.

4 Procedures In Certification

The drop testing section of MIL-STD-810G 516.6 includes several test methods and standards, such as Procedure I, Procedure IV, Procedure V, and Procedure VI. Each of these procedures is designed to simulate specific types of impact forces and environmental conditions, and the product being tested must pass all of the relevant tests to meet the standard's requirements.

Procedure I: This procedure involves dropping a product onto a flat, hard surface from various heights and angles, with the goal of simulating the impact forces that can occur when a product is dropped in normal use.

Procedure IV: This procedure simulates the impact forces that can occur when a product is dropped onto a hard surface while it is being transported or used.

Procedure V: This procedure involves dropping a product onto a hard surface while it is in operation, simulating the forces that can occur when a product is dropped during active use.

Procedure VI: This procedure simulates the impact forces that can occur when a product is dropped onto a hard surface while it is in storage, simulating the forces that can occur during transportation and storage.

Procedure I: This procedure involves dropping a product onto a flat, hard surface from various heights and angles, with the goal of simulating the impact forces that can occur when a product is dropped in normal use.

Procedure IV: This procedure simulates the impact forces that can occur when a product is dropped onto a hard surface while it is being transported or used.

Procedure V: This procedure involves dropping a product onto a hard surface while it is in operation, simulating the forces that can occur when a product is dropped during active use.

Procedure VI: This procedure simulates the impact forces that can occur when a product is dropped onto a hard surface while it is in storage, simulating the forces that can occur during transportation and storage.

Out-of-Procedure Inspection

In addition to the specific test procedures outlined in MIL-STD-810G, there are also general requirements for drop testing. For example, it must pass drop tests on 8 corners, 6 sides, and 12 sides, with the product fully operational and functional after each drop, and that the product be fully operational and functional after each drop. The standard also specifies the type of equipment and instrumentation required for drop testing, as well as the criteria for determining pass/fail results.

Overall, MIL-STD-810G's drop testing procedures are designed to ensure that military equipment can withstand the impact forces that can occur during transportation, storage, and use. By adhering to these testing procedures, manufacturers can ensure that their products meet the ruggedness and durability requirements of the military and other demanding applications.

Overall, MIL-STD-810G's drop testing procedures are designed to ensure that military equipment can withstand the impact forces that can occur during transportation, storage, and use. By adhering to these testing procedures, manufacturers can ensure that their products meet the ruggedness and durability requirements of the military and other demanding applications.

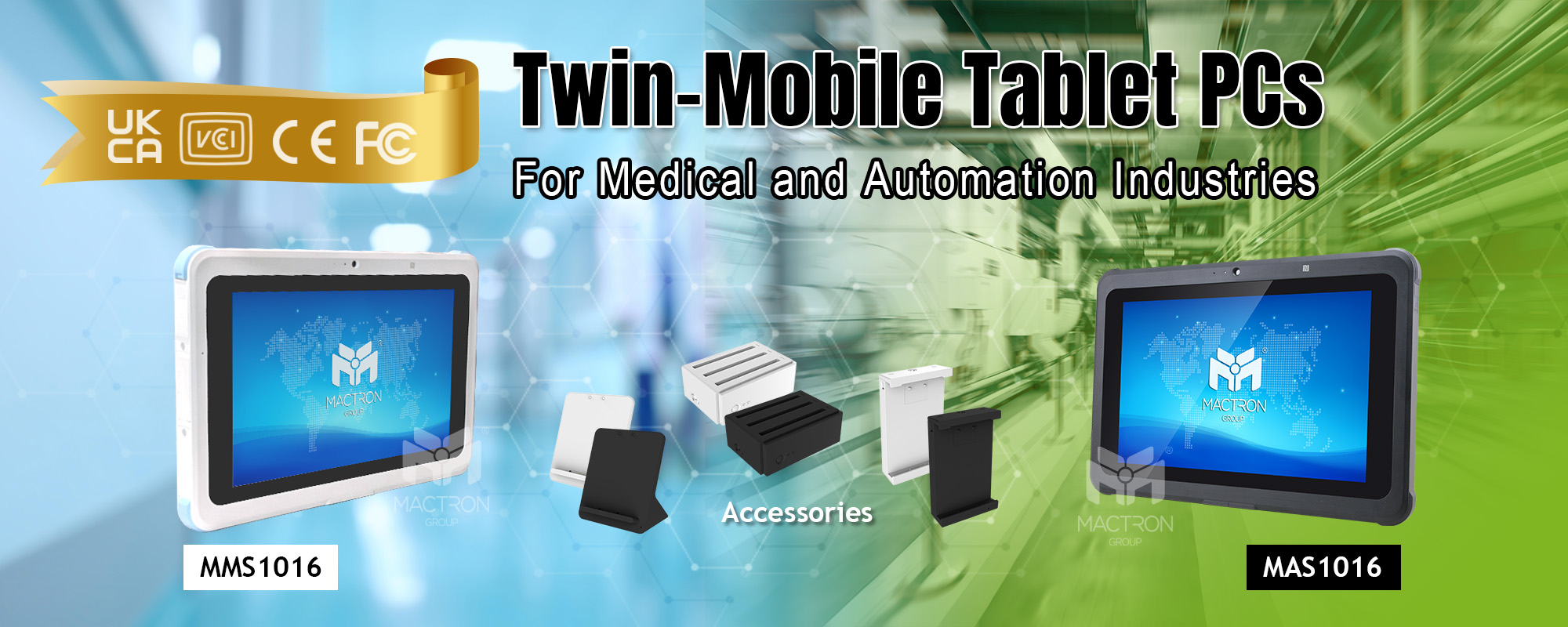

Check out MACTRON GROUP(MTG)’s brand new MAS1016 & MMS1016. This Rugged Mobile Tablet PC can support applications in several different fields, whether in medical treatment, industry or business, it can perform quite well. It can meet all your imagination.

0 comments:

Post a Comment