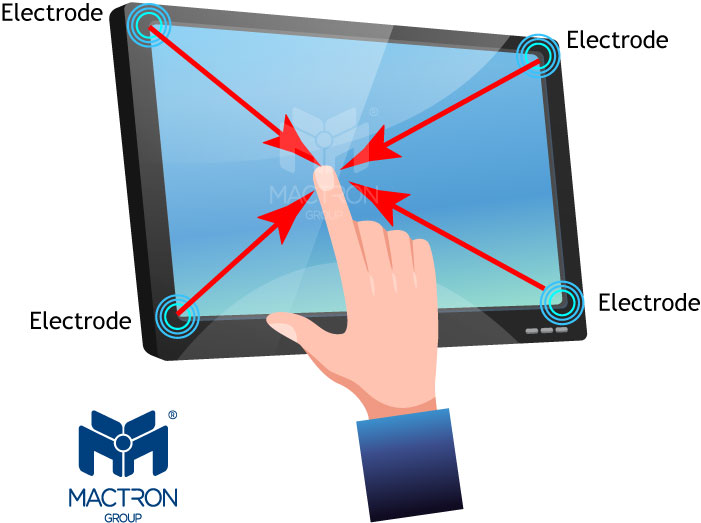

The principle of a capacitive touch screen

Resistive Touch Screen: A resistive touch screen consists of two layers of flexible transparent resistive film. When the screen is pressed by a finger or stylus, it generates pressure at the touch point, causing the two layers of resistive film to make contact and form a circuit. The touch panel detects the pressure and position information and sends it to the processor for processing.

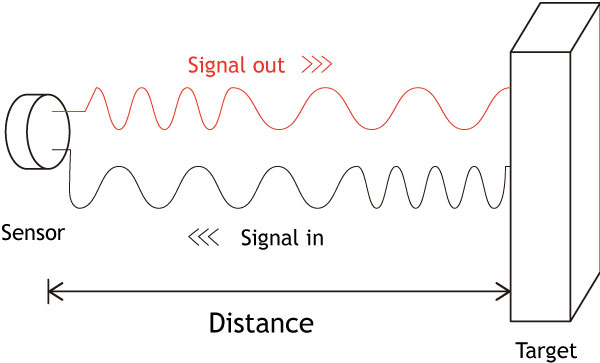

Capacitive Touch Screen (PCAP): A capacitive touch screen uses sensing electrodes to create an electric field on the screen. When a finger touches the screen, it changes the distribution of the electric field, which is detected by the sensing electrodes and converted into touch position information. Capacitive touch screens are divided into surface capacitance and projected capacitance types.

The advantages of PCAP touch screens

Multi-touch Capability:

PCAP touch screens can detect and track the positions and movements of multiple touch points simultaneously, supporting multi-finger gestures. This enables users to engage in more interactive experiences, such as pinch-to-zoom, rotation, and gesture controls.

Higher Precision and Accuracy:

PCAP touch screens detect touch positions by measuring changes in capacitance, rather than just pressure changes. Due to this principle, PCAP touch screens typically have higher precision and accuracy, enabling more precise touch operations.

PCAP touch screens have good anti-static interference capabilities, allowing them to accurately identify touch signals without being affected by external noise and interference. This enables stable touch operations in various environmental conditions.

Good Transparency:

The sensing electrodes of PCAP touch screens are made of transparent materials, which do not significantly affect the display effect of the screen, maintaining good visual quality. This makes touch screens more versatile in design, suitable for displays of various sizes and shapes.

Durability:

PCAP touch screens are typically composed of durable glass panels and electrode structures, providing high durability and scratch-resistant performance. This makes PCAP touch screens suitable for long-term, frequent use, and resistant to scratches or damage that may occur during daily use. In summary, PCAP touch screens have advantages over resistive touch screens in terms of multi-touch capability, high sensitivity and instant responsiveness, higher precision and accuracy, interference resistance, transparency, and durability. These advantages make PCAP touch screens a common and popular touch technology in modern devices.

Choose a PCAP touch Panel PC